Ball Mill Used in Minerals Processing Plant Prominer

This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, such as ore dressing, building material field, chemical industry, etc Due to the difference of its slurry discharging method, it is divided to two types: grid type ball mill and overflow type ball mill Compared with grid type ball mill, overflow China Grid Ball Mill Grinding Mill for Mineral Processing Plant and Construction Material, Find details about China Ball Mill, Grid Ball Mill from Grid Ball Mill Grinding Mill for Mineral Processing Plant and Construction Material Nanjing Sinonine Heavy Industry Science Technology Co, LtdChina Grid Ball Mill Grinding Mill for Mineral high quality ball mill for mineral processing plant with ce Ball mill is widely used in mining, smelting,road,building material and chemical it is the key equipment for grinding after the crush processThe mill consists of feeding device, driving assembly, rotating assembly, bearing unit,discharging assembly and foundation unitIt is a high technological enterprise that integrated research , high quality ball mill for mineral processing plant with Complete set of Graphite Beneficiation Equipment usually includes jaw crusher, ball mill, classifier, rod mills, agitation tanks, flotation machine, rotary dryers etc ZJH minerals as more than 30 years of professional mineral beneficiation equipment manufacturers, according to customer’s requirementsand actual situation, can provide ore testing, ore dressing experiments, process design, a complete set of equipment Ball Mills for Mining and Mineral Processing Industry50t Ball Mill for Mineral Processing, Ball Mill Machine for Benefication Plant picture from Zhengzhou Hengxing Heavy Equipment Co, Ltd view photo of Ball Mill for Benefication Process, Ball Mill Used for Benefication Process, Ball Mill EquipmentContact China Suppliers for More Products and PriceChina 50t Ball Mill for Mineral Processing, Ball Mill

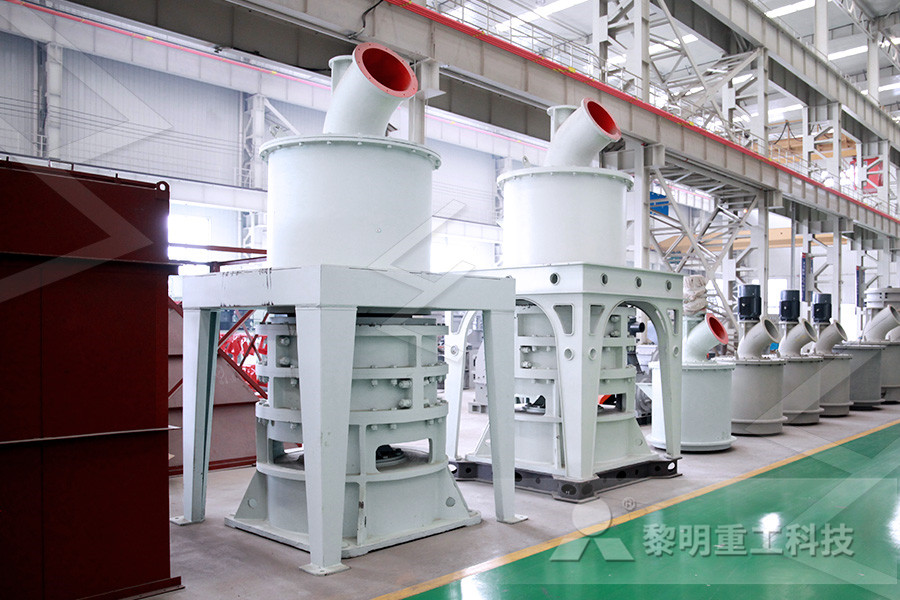

grinding mills used in mineral processing plants

The ball mill is a typical material grinder machine which widely used in the mineral processing plant, ball mill performs well in different material conditions either wet type grinding or dry type, and to grind the ores to a fine size main ball mill components cylinder, motor Ore ball mill sometimes called ore grinding mill, is generally used in mineral processing concentrator, processing materials include iron ore, copper ore, gold ore, molybdenum ore and all kinds of nonferrous metal oreBuy Ore Ball Mill for Mineral Processing Iron Gold Ball mill and rod mill solutions are available here at APT, providing an effective means for grinding and blending materials in preparation for mineral liberation, from rock to dust APT specifies and designs the entire circuit around the mill, to ensure that the target product size is achieved AvaBall Mill and Rod Mill Mineral Processing PlantsBulkbuy Mine Grinding Machine Ball Mill for Mineral Processing Plant price comparison, get China Mine Grinding Machine Ball Mill for Mineral Processing Plant price comparison from Grinding Machine Equipment Plant,Grinding Circuit Facilities manufacturers Mine Grinding Machine Ball Mill for Mineral This mill is constructed so that there is extreme flexibility of operation Additional machines can be added as desired, such as a second 18″ diameter shell to the Ball Mill, another 2cell flotation machine, a second classifier if required, etc LIST OF EQUIPMENT 1—5″x 6″ Type “H” Jaw Crusher 1—Belt Ore Feeder 1—30″x 18″ Ball MillSmall Mineral Processing Plant Design 911 Metallurgist

China Ball Mill of Mineral Processing Plant Gold

The overflow ball mill can be used for primary grinding or regrinding for the expected particle size Ball mill is one of the most commonly used mining equipment, which is widely used in mineral processing, construction materials, silicate and chemical industries【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a Ball Mills Industry Grinder for Mineral Processing Who We Are Founded in 1987, ZJH is mainly focus on producing and supply crushers,ore grinding equipment, mineral beneficiation equipment and laboratory and pilot equipment for Mines and Mineral Beneficiation Plants Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to reduce the operating cost ,to improve Ball Mills for Mining and Mineral Processing Industryball mill appliion in stone plants mineral processing Brief introduction of ball mill ball mill are giant drums that are filled to between and of their volume with freely moving grinding media in this case balls the diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasksball mill appliion in stone plants mineral processing DOVE ball mill is integrated and used in DOVE Portable and SemiStationary Hard Rock plants (Hard Rock processing plants) to efficiently grind the ore from primary deposit until the liberation size of valuable minerals is reached DOVE ball mill is the Ball Mill Ball Mills Wet Dry Grinding DOVE

Ball Mill Gold Processing Star Trace Pvt Ltd

Ball Mill: Gold Processing Equipment, Star Trace offers turnkey solutions for gold processing plants We are one of the leading project suppliers for gold plants and we work closely with our customers to fulfil their specific needs precise planetary ball mill could grind the specimens into the micron or nanometer size The instrument is suitable for grinding (dry grinding or wet grinding) and mixing of soft, medium hard, hard and brittle samples, and the grinding results are uniform and repeatablePrecise Planetary Ball Mills Crushers, Ball Mills and Mineral Processing Extractive Metallurgy explained in simple practical terms engineers and operators can understand Small Ball Mill Capacity Sizing Table Ball Mill Design/Power Calculation Plug N Play PlantsMineral Processing MetallurgyRoller Mill For Mineral Processing Plants Roller Mill For Mineral Processing Plants; The LOESCHE mill in the new processing plant for 152017 LOESCHE technology is at the heart of the plant, helping to develop the largescale phosphate rock deposit the most important raw material for the production of phosphatecontaining fertilizersRoller Mill For Mineral Processing Plants 1) Overload in overflow ball mills is due to the approach to a critical axial flow velocity for pulp of 0072 m/s 2) While so far important only with 50 and 55 m diameter mills, it should be found with smaller mills in combinations of very high circulating loads, excessive L/D ratios, very soft ores or coarse grinds 3 A proper balancing of lower Lf and higher F values can reduce the risk Dimensionality in ball mill dynamics SpringerLink

Ball Mills for Mining and Mineral Processing Industry

Who We Are Founded in 1987, ZJH is mainly focus on producing and supply crushers,ore grinding equipment, mineral beneficiation equipment and laboratory and pilot equipment for Mines and Mineral Beneficiation Plants Our aim is to work together with the Mining and Mineral Processing Industry for helping to carry on the production technical innovation, to reduce the operating cost ,to improve 【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a grinding method that reduces the product into a controlled final grind and a Ball Mills Industry Grinder for Mineral Processing China Mills catalog of EnergySaving Grate Ball Mill for Mineral Processing Plant, EnergySaving Overflow Ball Mill for Mineral Processing Plant provided by China manufacturer Yantai Huize Mining Engineering Co, Ltd, page1Mills Yantai Huize Mining Engineering Co, Ltd ball mill appliion in stone plants mineral processing Brief introduction of ball mill ball mill are giant drums that are filled to between and of their volume with freely moving grinding media in this case balls the diameter of the balls is between one and several centimetres to suit the application smaller balls for fine milling results and larger ones for coarser milling tasksball mill appliion in stone plants mineral processingThe L/D ratio of the ball mill was varied in four steps of 175, 21, 279 and 349, and the ball charge filling ratio was varied in three steps of 15%, 20% and 25% The experiments clearly indicated that the optimal L/D ratio and the optimal ball charge filling ratio are different for each feed finenessOptimization of continuous ball mills used for finish

Association Rules Mining Approach to Mineral Processing

mineral processing In many practical situations, standard asymptotic theory provides poor approximations, such as mineral plants operation A fuzzy mining algorithm is related to ball mill load, the stability of the grinding and 1) Overload in overflow ball mills is due to the approach to a critical axial flow velocity for pulp of 0072 m/s 2) While so far important only with 50 and 55 m diameter mills, it should be found with smaller mills in combinations of very high circulating loads, excessive L/D ratios, very soft ores or coarse grinds 3 A proper balancing of lower Lf and higher F values can reduce the risk Dimensionality in ball mill dynamics SpringerLinkMill and float plant modularized in a standard 40ft container Scope of supply included a loading bin for receipt of material, inclined screwfeeder for constant feed into the closed milling circuit The flotation circuit consists of the 3 stages of roughers, scavengers and cleaner cells with: froth agitators, air blowers, pumps, reagent Home MechProTech Process control challenges and opportunities in mineral processing The exception was the plants that used the extruders and sheet lines for the final product (eg, clear plastic interlayer for safety glass) Grinding is often finished with a ball mill, which differs from a SAG mill, as it relies on the steel alone for grinding Process control challenges and opportunities in Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design